Experts: Safety protocols should have prevented Amtrak crash deaths

Joe Carter was known as the railroad engineer who could thread a needle with a backhoe. He was on his machine last Sunday morning when a southbound Amtrak train barreled down the track at 106 mph near Chester, Pa., and caught Carter and his colleague Peter Adamovich in an area they likely thought had been shut down by dispatchers.

The seasoned veterans were focused on ballast between one of the two lines that carried 17.1 million travelers along the Northeast Corridor in 2015. And the sound of a modern train moving at 150 feet per second may not have been loud enough to alert them while working a noisy backhoe, railroad experts said.

At 7:54 a.m. the engine slammed into the backhoe, killing Carter, 61, and Adamovich, 59. The train derailed at almost the same spot where another train hit construction equipment on the track 28 years ago.

Technological advances over the past two centuries have made train travel safer than ever before, but even the best electronic systems can't prevent human error.

“This is an absolutely shouldn’t-have-happened situation,” said Allan Zarembski, a University of Delaware professor and director of the Railroad Engineering and Safety Program. “The safety procedures are in place to prevent exactly this.”

A directive from the Federal Railroad Administration to Amtrak last week suggests that a breakdown in communication resulted in a failure in safety protocols the day of the accident, April 3. FRA officials told Amtrak to conduct a “comprehensive review of basic and all pertinent safety rules and regulations” with maintenance of way workers and their supervisors — a review of the same federal regulations workers are trained on annually.

National Transportation Safety Board investigators have not said whether track maintenance was scheduled for Sunday morning or who was authorized to be on the rails at that time. They also have not said whether positive train control, a system used to automatically stop trains that may be danger of collision, was operating. Amtrak implemented the system in late December after a fatal derailment north of Philadelphia last May.

“If it all gets done right, this thing can never happen,” said Gus Ubaldi, an airport and railroad engineering expert with Robson Forensic, a legal consulting firm. “The problem with technology is that sometimes people will rely on it (solely). … Do you want to put all your faith in a piece of technology?”

Locals who live in the stretch of row homes that border the tracks in Chester said Amtrak employees had been working on the tracks for weeks before the accident.

Before workers go onto tracks, they are supposed to gain authority through a dispatcher, experts said. The process includes notifying dispatchers, conducting a safety briefing and checking on and off the tracks while performing maintenance.

Ubaldi said someone knew workers were on the tracks that Sunday morning.

Orders to repair rails start “way up in the brass hats," he added. "A machine like that doesn't go out on the track unless someone in transportation knows its out there.”

Always dangerous, sometimes deadly

This isn't the first time Amtrak has seen fatalities on the job. Last year, two employees died on the job – one while operating a Metrolink and one working trackside, according to Amtrak spokeswoman Christina Leeds. In 2015, 11 on-duty employees on railroads across the U.S. died as a result of a rail accidents, according to NTSB data.

The railroad labor union Brotherhood of Maintenance of Way Employees Division, which represents 35,000 men and women who work on the rails, said in a statement that more must be done to protect employees.

“There have been three track worker fatalities in Amtrak’s Northeast Corridor since March 1, 2016,” BMWED National President Freddie N. Simpson said. “This is totally unacceptable and points to systemic deficiencies in the safety culture at Amtrak.”

Union officials would not elaborate on the statement, other than to say they will release more information as it becomes available. Along with the Federal Railroad Administration and NTSB, the union is conducting its own investigation as well.

Those who knew Carter say he was a seasoned pro who knew the rules.

“With nearly 40 years on the rail, Carter can run countless pieces of machinery with finesse that earns him constant praise from his co-workers," says a story in the April 2015 Amtrak Engineering Mid-Atlantic publication. "Some say he could thread a needle with a backhoe if he tried.”

Victor Mercado, who Carter trained on the machinery, said in the publication that Carter was a mentor and role model.

“I’m no Joe Carter,” he said. “I get on equipment with him and watch what he does.” Mercado explained that he one day hoped to garner the same respect Carter had among his peers.

Carter’s family declined to speak for this story.

Crash prompts change

Back in 1988 following the Chester crash, the NTSB found fault with Amtrak for a multitude of reasons, the most apparent being that the organization did not provide adequate protection for workers, equipment and trains when tracks are taken out of service, according to the report.

Two on-duty Amtrak employees were able to ditch their equipment before a train collided with it on the tracks, but 20 people, including the locomotive engineer, were injured.

“A machine like that doesn't go out on the track unless someone in transportation knows its out there.”

Gus Ubaldi, airport and railroad engineering expert with Robson Forensic

The tower operator gave the clear for the track when workers were still in place, according to the report, causing the NTSB to question the reliability of the operator, as well as Amtrak in its screening process for workers.

One of the recommendations from the NTSB to Amtrak was to “develop and implement a procedure to prevent locomotives or trains from entering out-of-service train sections unless permission has been received from the person in charge of the out-of-service track.”

The Federal Railroad Administration later implemented stringent policies and procedures surrounding on-track work. The process of “gaining authority” of a track involves notifying the train dispatcher, reading back the plans for construction or maintenance and notifying the dispatcher again when work is complete.

No one knows exactly what happened on April 3, experts said, except for the fact that something went terribly wrong. Ubaldi said the union may be right in questioning whether the annual trainings on safety are making a difference.

“Being current doesn’t mean you're proficient,” Ubaldi said. “So yes, we have recurrent training. Maybe the question is: Is it taking? Is it sinking in?”

Classroom lessons

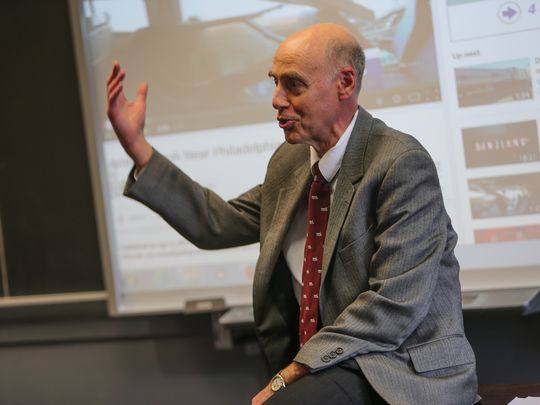

Last Thursday afternoon, Zarembski stood in front of a small class at University of Delaware, a bright screen behind him illuminating the steps Amtrak workers are required to take when gaining access onto the track. The train collision provided an early lesson to civil engineering students who may one day be doing the very jobs track workers killed Sunday were performing, he said.

Many have asked why the engineer couldn't stop the train on the straight piece of track. Officials said he initiated emergency brakes five seconds before the crash.

After a few math equations and some explaining, Zarembski determined the train would have needed about 30-50 seconds to come to a complete stop and about six-tenths to nine-tenths of a mile to do so.

“There was absolutely no way he could have stopped,” he told the class.

For the engineer to see the piece of maintenance equipment, recognize it’s a hazard far off in the distance and realize action must be taken requires time, Ubaldi said.

"When you're traveling 150 feet per second, two seconds means a lot," he said.

That’s the reality of railroading, an industry engraved in U.S. history for centuries and one that has gotten dramatically safer over the years. Every time workers step on the tracks, there is a risk of something going wrong. No piece of technology will take that away, Zarembski said.

“The one thing we know for sure,” Zarembski said of the April 3 crash, “is something went wrong.”

Политика конфиденциальности | Правила пользования сайтом